Optical Microscopy of Concrete and Related Material

Concrete Experts International offers services within optical microscopy of concrete and related materials such as aggregates for concrete, tiles, bricks and natural building stones.

Optical Microscopy of Concrete and Related Material

Concrete Experts International offers services within optical microscopy of concrete and related materials such as aggregates for concrete, tiles, bricks and natural building stones.

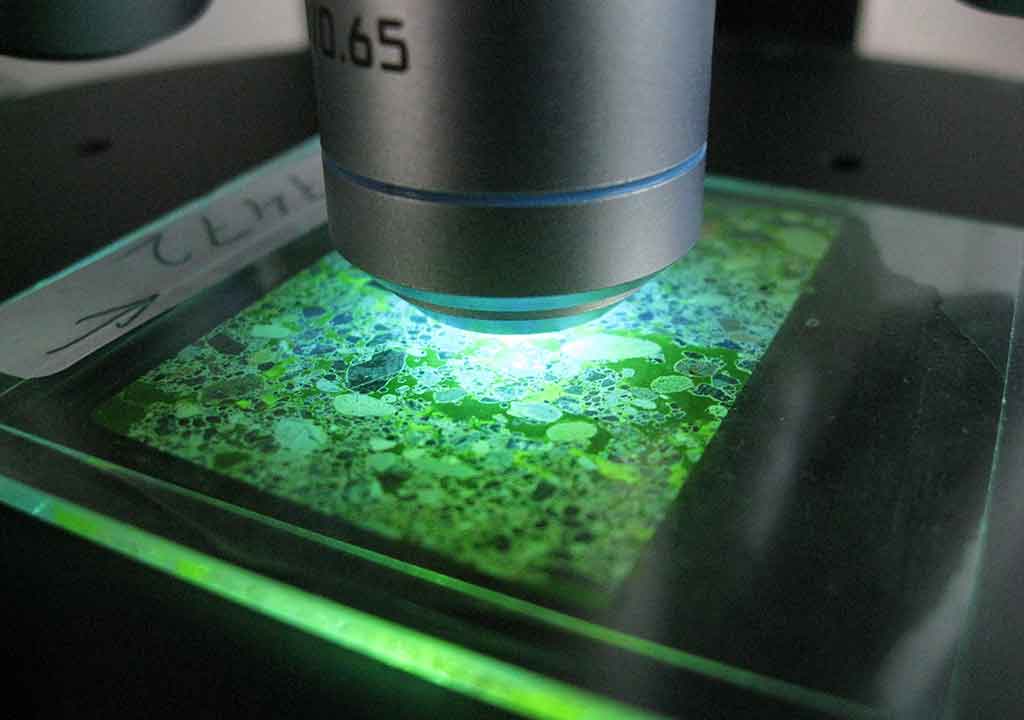

The fundamental element of optical microscopy is the preparation and examination of 20µm (0.020 mm) thick sections of concrete. In order to enhance the amount of information from the analysis CXI prefers to use thin sections impregnated by yellow fluorescent epoxy. The fluorescent thin section is analyzed in the optical microscope in order to assess:

- Quality assurance and optimization in the manufacturing process and of the final product

- Properties and long term performance

- Durability of concrete and other materials

- Evaluation of deterioration processes

- Development and improvement of new materials

Sections of concrete as thin as 20µm are semi transparent for light and therefore allows the examination by optical microscopy.

The thin section can be examined in four different light modes: ordinary light, polarized light, polarized light with gypsum plate inserted and fluorescent light.

Each of these light modes is used to examine different features in the concrete material. Ordinary light is used for general examination of the structure and composition of the material while polarized light with and without gypsum plate is used for mineral identification, detailed examination of the crystallinity and composition of the constituents of the material.

The fluorescent light mode is very useful for assessing variations in the porosity of materials. Porous areas appear yellow while dense areas will appear dark green in this light mode.

The large variation in intensities from yellow to dark green due to even slight variations in porosity of a material is also utilized for the determination of water to cement ratio in hardened concrete and mortar. A trained operator is thus capable of making a visual estimate of the water to cement ratio with an accuracy of +/- 0.02.

Besides providing detailed information about the composition and structure of the material examined, the thin section technique has additional advantages:

- It presents an undisturbed image of the original material.

- Once prepared, the thin sections can be stored for an indefinite time as documentation. This also enables later examinations to be carried out if necessary.

- Illustrative micrographs can easily be prepared to substantiate the technical results of the examination.

- Thin sections can be subjected to examinations by Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray analyses (EDX) without loosing their optical properties.

Concrete Experts International is highly experienced in the use of optical microscopy for identification and examination of concrete deterioration due to alkali silica reactions, sulfate attack, freeze-thaw damage, corrosion of reinforcement and more complex causes of damage.

CXI has experience in the examination and characterizations of other types of building materials as well as from the optimization of concrete production processes and performance.

The ability of optical microscopy to provide information about e.g. compositional homogeneity of mineral/inorganic based material makes it a valuable tool of documentation in the process of developing new building materials based on cement and other siliceous material.

All services are provided by the Danish Technological Institute >

Other Services

In cooperation with Danish Technological Institute > we provide the following services

Terms and definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

Terms and Definitions

The following small dictionary describes some of the terms used in concrete examination and description.

Agglomerate: 3 or more air voids in close contact

Aggregate: Component of the concrete consisting of a coarse aggregate fraction (more than 4 mm) and a fine aggregate fraction (less than 4 mm)

Alite: Tricalciumsilicate, C3S (3CaO-SiO2), a natural occurring mineral present in ordinary Portland cement.

Alkali silica reaction: Reaction between silica in the aggregates (e.g. chert, flint, micro-crystalline quartz), alkali (from cement, de-icing salt, sea water), calcium hydroxide and water. Alkali silica reaction causes aggregates to expand and cracks are formed radiating out into the ambient cement paste.

Alkali silica gel: A product of alkali silica reaction. Gel is usually clear, transparent and non-crystalline (amorphous), although in some cases it may crystallize. It expands during water absorption. Gel is usually found lining or filling cracks and air voids.

Aluminate phase: Tricalciumaluminate, C3A (3CaO-Al2O3)

Anhydrate: CaSO4

Belite: Dicalciumsilicate, C2S (2CaO-SiO2), natural occurring mineral present in ordinary Portland cement.

Bleeding: Water separation in the concrete. "Bleeding" is the phenomenon where water migrates towards the surface of the concrete and collects on the surface or underneath coarse aggregates. Seen as narrow voids along the interface between aggregate and cement paste. Calcium hydroxide may be deposited in the voids.

Calcium carbonate: CaCO3 , calcite, found as deposits in voids and cracks and on the surface.

Calcium hydroxide: Ca(OH)2, Portlandite, hydration product of C3S and C2S. Appears throughout the non-carbonated cement paste and occasionally as larger crystals in voids and cracks

Carbonation: Transformation of the calcium containing constituents of the concrete by reaction with the carbon dioxide in air. Calcium hydroxide is transformed to calcium carbonate and consequently the paste becomes chemically neutral.

Cement: The visible cement minerals are: C3S, C2S and C4AF. C3A is not visible.

Cement paste: Compound of hydration products from the cement-water reaction and unhydrated cement. Micro silica (MS) and fly ash (FA) is usually treated as part of the paste.

Cracks: Are divided in 3 groups in relation their width: coarse cracks are cracks wider than 0.1 mm, fine cracks varies from 0.01 - 0.1 mm and micro cracks are less than 0.01 mm. Cracks usually run in the cement paste; however, occasionally the aggregates are traversed. Cracks form either in the early (plastic stage) or at a later stage (fully hardened stage) in the life of the concrete .

Delayed Ettringite Formation (DEF): Hardened concrete that has been subjected to high-temperature heat curing or high internal hydration heat temperature may suffer from expansion and cracking during subsequent exposure to moisture. DEF is diagnosed by the presence of gaps around aggregate particles.

Entrained air: Usually defined as the small and medium sized spherical air voids with maximum size 0.5 - 1 mm

Entrapped air: Comprises irregular and angular air voids of all sizes

Ettringite: 3CaO.Al2O3.3CaSO4.32H2O. Needle shaped crystals of calcium sulfo-aluminate hydrate produced by constituents in the cement paste, including gypsum. It is also produced by sulfate attack on the concrete.

Ferrite phase: Tetracalciumaluminateferrite, C4AF (4CaO-Al2O3-Fe2O3)

Filled voids: Air voids with complete or partial filling of e.g. alkali silica gel, ettringite, calcium hydroxide, calcium carbonate or gypsum.

Friedel Salt (mono-chloride): 3CaO.Al2O3.CaCl2.10H2O

Gaps: Cracks observed all the way around aggregate particles in the interface zone between aggregate and cement paste. Gaps can be empty, or be partly or completely filled with ettringite. The width of the gaps is positively correlated with the size of the aggregate. Gaps are evidence of some sort of paste expansion occurring from delayed ettringite formation (DEF), freeze/thaw and sulfate attack.

Gypsum: CaSO4.2H2O, calcium sulfate which is found as a common constituent of cement. It is also produced by acid attack (sulfuric acid) on concrete.

Hydration: Reaction between cement and water, producing cement gel (cement paste, cement glue) serving as an adhesive in the concrete.

Mono-sulfate: 3CaO.Al2O3.CaSO4.12H2O

Plastic shrinkage: Shrinkage caused by strong drying of newly cast concrete. The result is often plastic shrinkage cracks in the concrete surface.

Plastic settlement: Settlement of fresh concrete, often causing plastic settlement cracks.

Re-crystallization: Dissolution of crystals and re-deposition either of the same mineral in a different form or of new minerals, mostly stabilized due to the presence of water.

Segregation: "Segregation" is the phenomenon where the concrete has no internal adhesion, and the mortar (therefore separates from the coarse aggregates.

Thaumasite: CaSiO3.CaSO4.CaCO3. A mineral not naturally present in concrete. Thaumasite may occur in concrete suffering from sulfate attack. The presence of thaumasite depends according to literature on temperature and presence of carbon dioxide.

w/c ratio: The ratio of water to cement by weight of the cement paste. If the cement paste contains fly ash (FA) or micro silica (MS) the addition of these materials can be taken into account using an activity factor and an equivalent w/c ratio can be calculated.

Contact Us

Concrete Experts International ApS

Gøngehusvej 242

DK-2950 Vedbæk