Failure Analysis and Materials Characterization

Petrographic analysis is a very valuable and indispensable tool in the fields of quality control and failure analysis of young as well as old concrete.

Failure Analysis and Materials Characterization

Petrographic analysis is a very valuable and indispensable tool in the fields of quality control and failure analysis of young as well as old concrete. Performing petrographic analyses in a logical sequence and using qualified personnel makes this type of analysis fundamental in concrete characterization as well as in any other materials characterization analysis.

Concrete Experts International offers petrographic services in the field of failure analysis of concrete and related materials as well as in materials characterization in general. CXI uses a combination of optical microscopy, scanning electron microscopy, and chemical analysis in their analysis. These types of analysis are fundamental in the understanding of natural as well as man made material and is well known in most natural sciences. Petrography is a term known from geology meaning, “the systematic characterization of rocks in hand specimen and thin section”.

A well-performed analysis should elucidate the responsibility and causes of failure, as well as suggestions for repair.

Systematics during analysis guarantee that no important information has been lost or overlooked and that the obtained conclusions are well documented and reliable.

The staff of Concrete Experts International is highly qualified and has a worldwide reputation in failure analysis of concrete and materials characterization in general. The basis for providing our clients with a superior well documented failure analysis is the following suit of investigations:

- Field examination of the structure

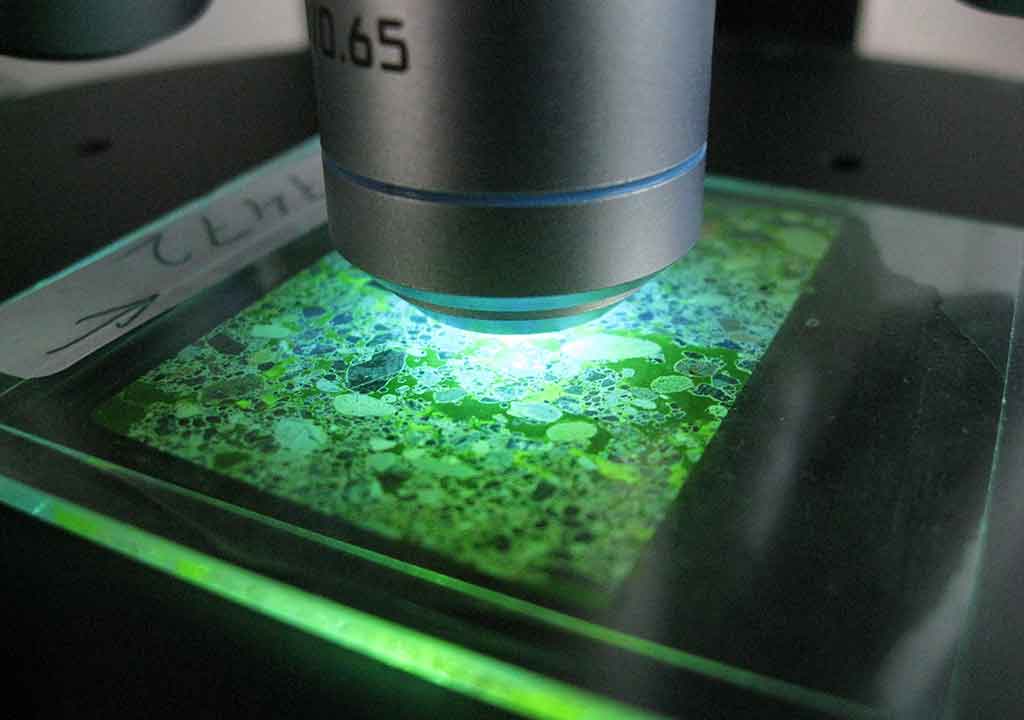

- Petrographic analysis consisting of a macroscopic examination of cores and other types of samples and a microscopic examination of fluorescent impregnated thin sections prepared from concrete cores.

- Determination of w/c

- Evaluation of raw materials and production data and methods – if available.

Depending on the actual case the following types of analysis may be added to increase level of documentation:

- Scanning electron microscopy (SEM) of fluorescent polished thin sections

- XRD analysis of powdered material

- Chemical analysis e.g. sulfate and chloride analysis

- Absorption, air void analysis etc.

CXI uses yellow fluorescent microscopy during petrographic examination making determination of w/c easy and emphasize defects such as micro-cracking and bleeding in concrete.

The staff of CXI has extensive experience in diagnosing all types of deterioration mechanisms occurring in concrete e.g. alkali silica reaction, delayed ettringite formation, external sulfate attack, acid attack and carbonation.

CXI is highly skilled in the interpretation of the micro-structural appearance of materials which makes CXI able to evaluate whether a failure is caused by faulty mix design or poor workmanship during casting and curing.

All services are provided by the Danish Technological Institute >

Other Services

In cooperation with Danish Technological Institute > we provide the following services

Terms and definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

Terms and Definitions

The following small dictionary describes some of the terms used in concrete examination and description.

Agglomerate: 3 or more air voids in close contact

Aggregate: Component of the concrete consisting of a coarse aggregate fraction (more than 4 mm) and a fine aggregate fraction (less than 4 mm)

Alite: Tricalciumsilicate, C3S (3CaO-SiO2), a natural occurring mineral present in ordinary Portland cement.

Alkali silica reaction: Reaction between silica in the aggregates (e.g. chert, flint, micro-crystalline quartz), alkali (from cement, de-icing salt, sea water), calcium hydroxide and water. Alkali silica reaction causes aggregates to expand and cracks are formed radiating out into the ambient cement paste.

Alkali silica gel: A product of alkali silica reaction. Gel is usually clear, transparent and non-crystalline (amorphous), although in some cases it may crystallize. It expands during water absorption. Gel is usually found lining or filling cracks and air voids.

Aluminate phase: Tricalciumaluminate, C3A (3CaO-Al2O3)

Anhydrate: CaSO4

Belite: Dicalciumsilicate, C2S (2CaO-SiO2), natural occurring mineral present in ordinary Portland cement.

Bleeding: Water separation in the concrete. "Bleeding" is the phenomenon where water migrates towards the surface of the concrete and collects on the surface or underneath coarse aggregates. Seen as narrow voids along the interface between aggregate and cement paste. Calcium hydroxide may be deposited in the voids.

Calcium carbonate: CaCO3 , calcite, found as deposits in voids and cracks and on the surface.

Calcium hydroxide: Ca(OH)2, Portlandite, hydration product of C3S and C2S. Appears throughout the non-carbonated cement paste and occasionally as larger crystals in voids and cracks

Carbonation: Transformation of the calcium containing constituents of the concrete by reaction with the carbon dioxide in air. Calcium hydroxide is transformed to calcium carbonate and consequently the paste becomes chemically neutral.

Cement: The visible cement minerals are: C3S, C2S and C4AF. C3A is not visible.

Cement paste: Compound of hydration products from the cement-water reaction and unhydrated cement. Micro silica (MS) and fly ash (FA) is usually treated as part of the paste.

Cracks: Are divided in 3 groups in relation their width: coarse cracks are cracks wider than 0.1 mm, fine cracks varies from 0.01 - 0.1 mm and micro cracks are less than 0.01 mm. Cracks usually run in the cement paste; however, occasionally the aggregates are traversed. Cracks form either in the early (plastic stage) or at a later stage (fully hardened stage) in the life of the concrete .

Delayed Ettringite Formation (DEF): Hardened concrete that has been subjected to high-temperature heat curing or high internal hydration heat temperature may suffer from expansion and cracking during subsequent exposure to moisture. DEF is diagnosed by the presence of gaps around aggregate particles.

Entrained air: Usually defined as the small and medium sized spherical air voids with maximum size 0.5 - 1 mm

Entrapped air: Comprises irregular and angular air voids of all sizes

Ettringite: 3CaO.Al2O3.3CaSO4.32H2O. Needle shaped crystals of calcium sulfo-aluminate hydrate produced by constituents in the cement paste, including gypsum. It is also produced by sulfate attack on the concrete.

Ferrite phase: Tetracalciumaluminateferrite, C4AF (4CaO-Al2O3-Fe2O3)

Filled voids: Air voids with complete or partial filling of e.g. alkali silica gel, ettringite, calcium hydroxide, calcium carbonate or gypsum.

Friedel Salt (mono-chloride): 3CaO.Al2O3.CaCl2.10H2O

Gaps: Cracks observed all the way around aggregate particles in the interface zone between aggregate and cement paste. Gaps can be empty, or be partly or completely filled with ettringite. The width of the gaps is positively correlated with the size of the aggregate. Gaps are evidence of some sort of paste expansion occurring from delayed ettringite formation (DEF), freeze/thaw and sulfate attack.

Gypsum: CaSO4.2H2O, calcium sulfate which is found as a common constituent of cement. It is also produced by acid attack (sulfuric acid) on concrete.

Hydration: Reaction between cement and water, producing cement gel (cement paste, cement glue) serving as an adhesive in the concrete.

Mono-sulfate: 3CaO.Al2O3.CaSO4.12H2O

Plastic shrinkage: Shrinkage caused by strong drying of newly cast concrete. The result is often plastic shrinkage cracks in the concrete surface.

Plastic settlement: Settlement of fresh concrete, often causing plastic settlement cracks.

Re-crystallization: Dissolution of crystals and re-deposition either of the same mineral in a different form or of new minerals, mostly stabilized due to the presence of water.

Segregation: "Segregation" is the phenomenon where the concrete has no internal adhesion, and the mortar (therefore separates from the coarse aggregates.

Thaumasite: CaSiO3.CaSO4.CaCO3. A mineral not naturally present in concrete. Thaumasite may occur in concrete suffering from sulfate attack. The presence of thaumasite depends according to literature on temperature and presence of carbon dioxide.

w/c ratio: The ratio of water to cement by weight of the cement paste. If the cement paste contains fly ash (FA) or micro silica (MS) the addition of these materials can be taken into account using an activity factor and an equivalent w/c ratio can be calculated.

Contact Us

Concrete Experts International ApS

Gøngehusvej 242

DK-2950 Vedbæk