RapidAir 457 – the fast air void analyzer

Get an automatic test of air void distribution in hardened concrete in less than 10 minutes in your laboratory

Increased productivity

Operator independent

Excellent repeatability

Excellent reproducibility

Good accuracy

Terms and Definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

1600% faster compared to conventional manual analysis

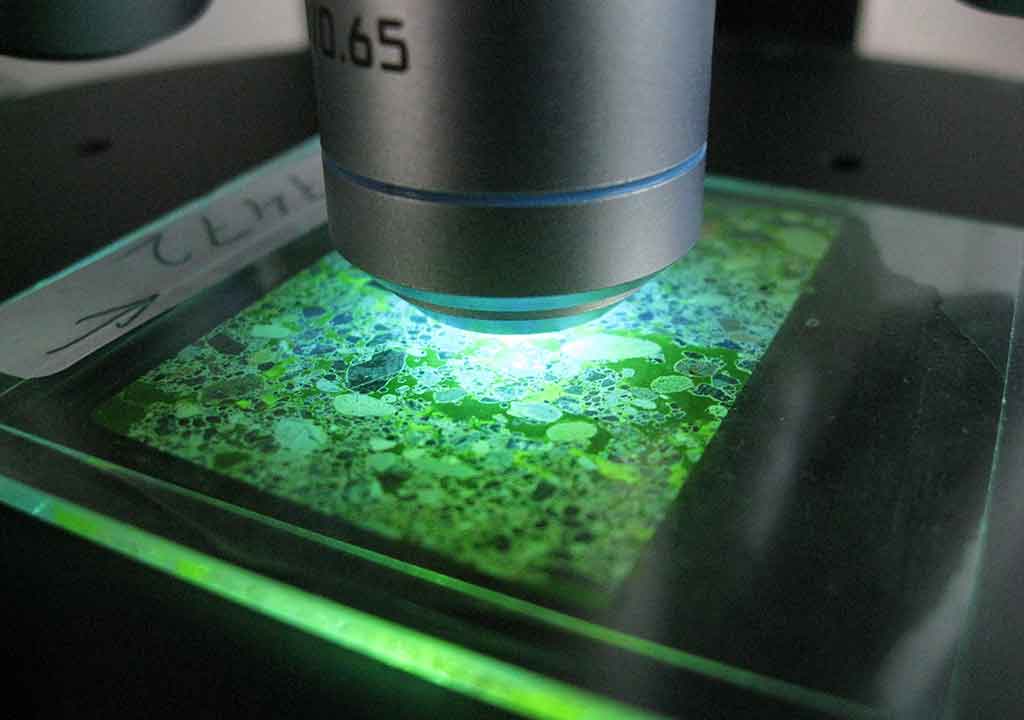

The RapidAir 457 equipment provides an automatic system for analyzing the air content in hardened concrete. The analysis time with the RapidAir 457 system is less than 10 minutes, which should be compared to the 4-6 hours normally required for manual analysis with conventional type of equipment.

The system can replace the manual test performed as described in the ASTM designation C457/C457M-16 procedure A, B and C “Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete” or the test performed according to EN 480-11 “Determination of air void characteristics in hardened concrete”.

Free Support included

With the purchase of a RapidAir 457 system, Concrete Experts International will provide free of charge half a day online training course in performing sample preparation and air void analysis. For a longer course or a seminar at the client’s office, arrangements can be made. Please contact Concrete Experts International for details >

Get more documentation

Deterioration Mechanisms in Concrete

When analyzing damaged concrete the following deterioration mechanisms are frequently found to have caused concrete failure, either as a single mechanism or as a combination of two or more mechanisms

We have been Concrete Experts for more than 25 Years

Concrete Experts International(CXI) is a consulting company, specializing in the fields of concrete technology, microanalysis of cement based materials, product optimization, development and characterization.

We develop and sell the RapidAir 457 automatic air void analyzer:

RapidAir 457 have been on the marked since 2002

RapidAir 457 can be found in more than 100 laboratories

RapidAir 457 is sold to Universities, Consultant firms, Cement and Concrete Producers, Construction Products Technologies Companies and to quality control on large Construction sites all over the world.

Services

In cooperation with Danish Technological Institute > we provide the following services

Client Testimonials

“It is a pleasure to recommend you to make use of Concrete Experts International’s

services. Their knowledge and experience is outstanding regarding new technology

developments with cement and concrete and related materials as well as for expert

investigations of the durability and deterioration of field concrete. The special, combined scientific-engineering experience makes the company a welcomed, consulting newcomer.”

“…On my behalf, as well as on behalf of my client, I want to thank all of you for the tremendous effort which you put forth in the case. You all did an excellent job. The work you did in a limited time period was first rate. I was particularly impressed with the high quality reports which you prepared.”

“…Thanks for all your help in the case. Your experience, research and testimony were

very important and critical to the successful outcome. These cases are always complex, but by having the right experts, we greatly improved our defense.”

Terms and definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

Terms and Definitions

The following small dictionary describes some of the terms used in concrete examination and description.

Agglomerate: 3 or more air voids in close contact

Aggregate: Component of the concrete consisting of a coarse aggregate fraction (more than 4 mm) and a fine aggregate fraction (less than 4 mm)

Alite: Tricalciumsilicate, C3S (3CaO-SiO2), a natural occurring mineral present in ordinary Portland cement.

Alkali silica reaction: Reaction between silica in the aggregates (e.g. chert, flint, micro-crystalline quartz), alkali (from cement, de-icing salt, sea water), calcium hydroxide and water. Alkali silica reaction causes aggregates to expand and cracks are formed radiating out into the ambient cement paste.

Alkali silica gel: A product of alkali silica reaction. Gel is usually clear, transparent and non-crystalline (amorphous), although in some cases it may crystallize. It expands during water absorption. Gel is usually found lining or filling cracks and air voids.

Aluminate phase: Tricalciumaluminate, C3A (3CaO-Al2O3)

Anhydrate: CaSO4

Belite: Dicalciumsilicate, C2S (2CaO-SiO2), natural occurring mineral present in ordinary Portland cement.

Bleeding: Water separation in the concrete. "Bleeding" is the phenomenon where water migrates towards the surface of the concrete and collects on the surface or underneath coarse aggregates. Seen as narrow voids along the interface between aggregate and cement paste. Calcium hydroxide may be deposited in the voids.

Calcium carbonate: CaCO3 , calcite, found as deposits in voids and cracks and on the surface.

Calcium hydroxide: Ca(OH)2, Portlandite, hydration product of C3S and C2S. Appears throughout the non-carbonated cement paste and occasionally as larger crystals in voids and cracks

Carbonation: Transformation of the calcium containing constituents of the concrete by reaction with the carbon dioxide in air. Calcium hydroxide is transformed to calcium carbonate and consequently the paste becomes chemically neutral.

Cement: The visible cement minerals are: C3S, C2S and C4AF. C3A is not visible.

Cement paste: Compound of hydration products from the cement-water reaction and unhydrated cement. Micro silica (MS) and fly ash (FA) is usually treated as part of the paste.

Cracks: Are divided in 3 groups in relation their width: coarse cracks are cracks wider than 0.1 mm, fine cracks varies from 0.01 - 0.1 mm and micro cracks are less than 0.01 mm. Cracks usually run in the cement paste; however, occasionally the aggregates are traversed. Cracks form either in the early (plastic stage) or at a later stage (fully hardened stage) in the life of the concrete .

Delayed Ettringite Formation (DEF): Hardened concrete that has been subjected to high-temperature heat curing or high internal hydration heat temperature may suffer from expansion and cracking during subsequent exposure to moisture. DEF is diagnosed by the presence of gaps around aggregate particles.

Entrained air: Usually defined as the small and medium sized spherical air voids with maximum size 0.5 - 1 mm

Entrapped air: Comprises irregular and angular air voids of all sizes

Ettringite: 3CaO.Al2O3.3CaSO4.32H2O. Needle shaped crystals of calcium sulfo-aluminate hydrate produced by constituents in the cement paste, including gypsum. It is also produced by sulfate attack on the concrete.

Ferrite phase: Tetracalciumaluminateferrite, C4AF (4CaO-Al2O3-Fe2O3)

Filled voids: Air voids with complete or partial filling of e.g. alkali silica gel, ettringite, calcium hydroxide, calcium carbonate or gypsum.

Friedel Salt (mono-chloride): 3CaO.Al2O3.CaCl2.10H2O

Gaps: Cracks observed all the way around aggregate particles in the interface zone between aggregate and cement paste. Gaps can be empty, or be partly or completely filled with ettringite. The width of the gaps is positively correlated with the size of the aggregate. Gaps are evidence of some sort of paste expansion occurring from delayed ettringite formation (DEF), freeze/thaw and sulfate attack.

Gypsum: CaSO4.2H2O, calcium sulfate which is found as a common constituent of cement. It is also produced by acid attack (sulfuric acid) on concrete.

Hydration: Reaction between cement and water, producing cement gel (cement paste, cement glue) serving as an adhesive in the concrete.

Mono-sulfate: 3CaO.Al2O3.CaSO4.12H2O

Plastic shrinkage: Shrinkage caused by strong drying of newly cast concrete. The result is often plastic shrinkage cracks in the concrete surface.

Plastic settlement: Settlement of fresh concrete, often causing plastic settlement cracks.

Re-crystallization: Dissolution of crystals and re-deposition either of the same mineral in a different form or of new minerals, mostly stabilized due to the presence of water.

Segregation: "Segregation" is the phenomenon where the concrete has no internal adhesion, and the mortar (therefore separates from the coarse aggregates.

Thaumasite: CaSiO3.CaSO4.CaCO3. A mineral not naturally present in concrete. Thaumasite may occur in concrete suffering from sulfate attack. The presence of thaumasite depends according to literature on temperature and presence of carbon dioxide.

w/c ratio: The ratio of water to cement by weight of the cement paste. If the cement paste contains fly ash (FA) or micro silica (MS) the addition of these materials can be taken into account using an activity factor and an equivalent w/c ratio can be calculated.

Contact Us

Concrete Experts International ApS

Gøngehusvej 242

DK-2950 Vedbæk